To celebrate Earth Day, Design World published an article on how design engineers can help reduce the environmental impact of industry. In 2011, the Energy Information Administration (EIA) found that the industrial sector was responsible for 51 percent of global energy consumption. Of the Industry’s energy use, 25 percent was in the form of losses. While this poses a major problem, author Danielle Collins offers several tips for how designers can reverse this environmental impact. Here are some of the things we learned:

Proper Sizing Helps Eliminate Inefficiency:

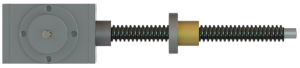

According to the article, “For linear motion components and systems, no other aspect of design has as much influence on energy use and efficiency as their physical size. Not only does proper sizing ensure the best performance for the application, avoiding waste in terms of scrap, rework, and over- or under-production. It also ensures that the driving equipment, whether electric, pneumatic or hydraulic, is not over-sized, which results in higher energy consumption.”

Collins uses linear bearings as an example to make her point. When larger bearings are used, larger motors, couplings and mounts also have to be used to create a proper inertia match, While keeping safety factors in mind, Collins says that all the weight necessary to accommodate the large bearings leads to overall inefficiency.

Regular Maintenance Reduces Energy Consumption:

As equipment goes through cycle after cycle, eventually the lubrication will break down, which increases the friction and decreases efficiency. According to Collins, this leads to other parts such as the motor, gearboxes and cylinders to work harder and consume more energy.

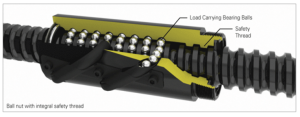

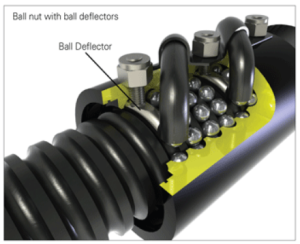

Collins believes that although equipment maintenance isn’t so much the concern of the engineers, designing equipment that is easy to maintain, such as that with ball chains or built-in lubrication systems, will more than likely keep machines running smoother and with less energy than those not built with low-maintenance considerations.

According to Collins, “Reducing the quantity and intervals for lubrication can also have a significant impact on the environmental footprint of a machine. A typical machine tool will have at least three linear axes of motion, with four bearings per axis, for a total of twelve bearings per machine. With approximately 250,000 machine tools produced each year, that’s over 3 million linear bearings to be lubricated! The potential for environmental impact due to lubricating greases and oils is considerable. Not to mention the energy required to move the axes.”

To read the full article and find out more on how designers can reduce energy consumption, click here.