The following is taken from an excellent white paper from Ron Givannone, Director of Application Engineering and Business Operations at Nook Industries (hyperlink). Titled “How to Size a Worm Gear Jack,” it looks at the key factors in figuring out what size and configuration of jack will work based on the needs of your application. Over the next few weeks, we’ll look at the different factors, and offer a bit more background.

This week, how Horsepower limitations can affect jack sizing.

When determining the lifting power of a jack, it’s a common mistake to assume the lifting capabilities of a jack are determined solely by its tonnage size. The load’s capacity is more often determined by its horsepower limitations. For example, a 10-ton jack may only be able to lift a one-ton load, because it is temperature-limited by the working horsepower it requires to lift the load.

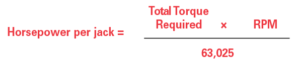

The horsepower limit of the jack is a result of its ability to dissipate the heat generated from the inefficiencies of its components. The maximum horsepower value represents the point at which the heat that is generated by the working horsepower to move a given load meets the maximum temperature of the internal components. The working horsepower to move a given load is calculated by using the following formula:

How well a jack can dissipate heat is influenced by many application-specific variables, including mounting, environment, duty cycle and lubrication. The best way to determine whether performance is within horsepower limits is to measure the jack temperature. The temperature of the housing near the worm gear must not exceed 200 degrees Fahrenheit.

Looking for help in figuring out the right horsepower? Here are some tools: