Here’s our 5th installment looking at the individual issues affecting Worm Gear system design originally highlighted in the white Paper “How to Size a Worm Gear Jack.” This posts looks at the expected life of a worm gear jack.

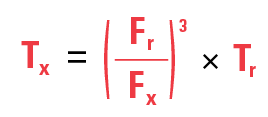

One of the benefits of using ball screw-style jacks is the ability to predict the theoretical life of the ball screw. The life of a ball nut used in a ball screw-style jacks can be easily calculated by using the following formula:

WHERE:

Tx = Travel other than rated load

Fr = Rated Dynamic Load for the ball nut

Fx = Actual or Equivalent load

Tr = Rated Travel Life. For inch screws this is equal to 1,000,000 inches

For manufacturers wishing to extend the life of their screws, it can be beneficial to order a larger size jack than normally required, extending the life of the screw.

Since jack products often work in environments full of dirt and debris, manufacturers take multiple precautions to keep out contamination and preserve the life of the screw. Some manufacturers utilize bellows boots that expand and contract as the nut moves along to keep the lift shaft covered from contamination. Bellows boots can be supplied in numerous materials so that they may be applied in even the most extreme applications.

With ball screw jacks, another form of protection manufacturers use is wipers. Nut wipers can be felt or plastic, and brush the nut free of any dirt or other contaminants, keeping contaminants from entering the ball nut.

Related tools: