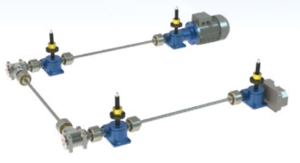

In worm gear screw jacks, the “U” arrangement’s configuration is often preferred for manufacturers in the food industry.

For example, a leading cookie manufacturer could be adding a new product that requires a greater distance to the top heating element of the conveyor oven. The oven originally only had a static-top heating element and with this new order, it needs to be adjustable up to 14 inches. The top heating element weighs 5,000 pounds. The manufacturer anticipates only making adjustments to the height once or twice a month.

For example, a leading cookie manufacturer could be adding a new product that requires a greater distance to the top heating element of the conveyor oven. The oven originally only had a static-top heating element and with this new order, it needs to be adjustable up to 14 inches. The top heating element weighs 5,000 pounds. The manufacturer anticipates only making adjustments to the height once or twice a month.

Our specifications for the U arrangement include a single 5-Horsepower 1750 AC Motor that allows full travel in 36 seconds, food-grade grease, compression load and a double safety factor. The actuators and power train must be located outside of the oven frame. Travel rate is negligible as long as the total travel can be reached in less than 60 seconds. The application’s infrequent cycles makes the use of a machine screw jack the best fit.

Upright rotating jacks allow the jacks to be easily retrofitted to the existing oven with minimal modifications. The jacks will be fully loaded in both the retracted and extended position, but because of the retrofit condition, having a support bearing on the lift shaft will not be possible. A 10-ton jack was selected for the mounting condition to fulfill safety requirement.

For calculating column strength, check out Nook’s calculator, as well as other useful engineering calculators here.