Of all the screws in industry used for motion, ball screws provide unique benefits when compared to other standards, such as roller screws or acme screws. Here are just three of the benefits to using ball screws in your future applications.

Of all the screws in industry used for motion, ball screws provide unique benefits when compared to other standards, such as roller screws or acme screws. Here are just three of the benefits to using ball screws in your future applications.

High Efficiency – Ball screws typically operate at a minimum of 90 percent efficiency, which makes them an optimal choice in converting rotary motion into precision linear motion.

Load Capabilities – A part of what makes ball screws versatile in so many industries is their ability to carry remarkably heavy loads at fast, efficient speeds.

Cost-Efficient – In the long run, ball screw systems can prove to be a cost-effective alternative to pneumatic or hydraulic systems, which require constant electrical and air power.

What are some of the other ways ball screws have enhanced your business? Let us know below.

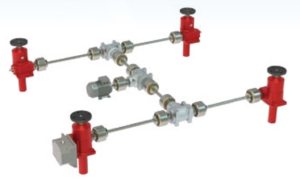

For example, a leading cookie manufacturer could be adding a new product that requires a greater distance to the top heating element of the conveyor oven. The oven originally only had a static-top heating element and with this new order, it needs to be adjustable up to 14 inches. The top heating element weighs 5,000 pounds. The manufacturer anticipates only making adjustments to the height once or twice a month.

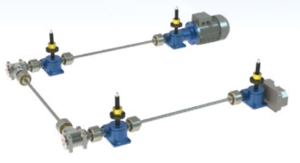

For example, a leading cookie manufacturer could be adding a new product that requires a greater distance to the top heating element of the conveyor oven. The oven originally only had a static-top heating element and with this new order, it needs to be adjustable up to 14 inches. The top heating element weighs 5,000 pounds. The manufacturer anticipates only making adjustments to the height once or twice a month. An example of this arrangement could be a manufacturer of steel frames for the commercial dairy industry is building a material lift which contains a stack of prefabricated frames. The material lift will index up as each frame is removed by an automated grip from the top of the stack. The jack will index up 1 inch in 2 seconds every 30 seconds. After the last frame is removed, the jacks will fully retract to the collapsed position in 6 seconds waiting for the next load of frames. Complete cycle time is 10 minutes running 6 hours per day, 5 days a week. The design calls for a four-jack arrangement lifting from underneath the lifting stage, driven by a single motor.

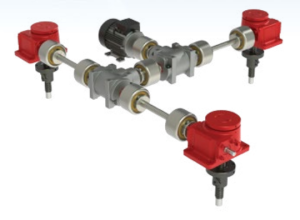

An example of this arrangement could be a manufacturer of steel frames for the commercial dairy industry is building a material lift which contains a stack of prefabricated frames. The material lift will index up as each frame is removed by an automated grip from the top of the stack. The jack will index up 1 inch in 2 seconds every 30 seconds. After the last frame is removed, the jacks will fully retract to the collapsed position in 6 seconds waiting for the next load of frames. Complete cycle time is 10 minutes running 6 hours per day, 5 days a week. The design calls for a four-jack arrangement lifting from underneath the lifting stage, driven by a single motor. Well, for a manufacturer looking to periodically raise and lower a cylindrical mixer 8 inches during the mixing cycle to allow product testing, the T arrangement ensures the load is lifted uniformly and safely.

Well, for a manufacturer looking to periodically raise and lower a cylindrical mixer 8 inches during the mixing cycle to allow product testing, the T arrangement ensures the load is lifted uniformly and safely.