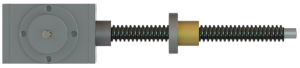

CC Actuators are a combination of an electric motor and an acme screw or a high efficiency ball screw. They are designed to be ready to install directly into any industrial or commercial application. They are ideally suited for any OEM application where linear motion is needed. These high-quality actuators feature:

- Durable construction

- Dependable performance

- Long-life operation

- High repeatability

- Operation in either compression or tension loading applications

- Adjustable limit switches

- Lifetime lubrication

- Mechanical overload protection

- Corrosion resistant exterior surfaces

The most common applications are;

- Telecommunications

- Architectural Automation

- Medical and Hospital Equipment

- Semiconductor

- Food Processing

- Farm Equipment

- Satellite Dish and Antenna Positioning

These rugged solutions come in standard travels of 4”, 12”, 18”, 24” or 36” with duty cycles typically around 30% max “on-time” of 5 minutes at rated load. Further versatility is provided by temperature ratings ranging from -30 to +160 F. Here’s a brief list of typical components, and what to look for when specifying;

Clutch – Should be heavy duty, in order to properly protect gears and components in the event of overload or overtravel.

Load Sensitive Brake – Should safely maintain the actuator’s position when at rest, without consuming power.

Boot – An optional accessory, but important in applications where you will want to protect the actuator tube from contaminants.

Limit Switch – Screw type limit switches offer precise positioning for travel up to 36”. Their design should allow for easily setting limits at both ends of travel. Optionally, Precision Limit Switches are typically available for shorter travel (under 24”) and will provide higher resolution adjustment.

Ball Screw – Look for precision ball screws made of high grade materials for greater efficiency & longer life

Sensors – There are a wide variety of sensor options for stroke control. Application needs should be the primary consideration when selecting, so look for a provider who offers a range.

Keyed – CC Linear Actuators may be ordered with a feature that allows the actuator tube to extend (retract) without being connected to the load. This key also reduces torque in clevises.