In order to get the most life and best applications out of your bearings, it’s important to understand the size of the load, how the load will be applied and the length of the stroke. Applying too much weight to a load can significantly reduce the life and efficiency of your bearings. Also, incorrectly distributing the weight on the load can be harmful. In addition to some helpful design considerations, let’s take a look at the load considerations below.

Load ratings are the required design life, shaft hardness and bearing dynamic that affect the load and can be applied to a linear bearing. Two dynamic load ratings are given for each bearing size based on the rotational orientation of the bearing.

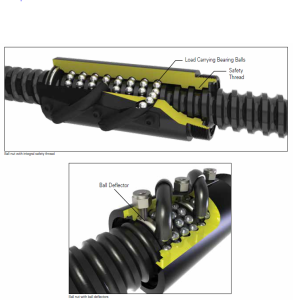

The normal load rating is used in applications where the orientation of the ball tracks relative to the load cannot be controlled. The normal load rating is based on a load imposed directly over a single ball track. The normal load rating shown in the specification tables is slightly greater than would be mathematically calculated based on one track loading, because it assumes that the load is shared to some degree by one or more of the adjacent ball tracks.

The maximum load rating assumes that the load is applied midway between two ball tracks as illustrated below. In this orientation the load is distributed over the maximum number of bearing balls.

The normal and maximum load ratings are based on a Rc 60 shaft hardness and a travel life of two million inches. For linear bearing system operating at less than full rated load, the Load-Life Curve may be used to determine the travel life expectancy.

An equivalent load value can be calculated when sizing linear bearings for applications at conditions other than maximum rating.