Due to their steel-on-steel design, the bearing industry has developed ways to calculate the life expectancy of ball screws. However, other factors, such as contamination, lubrication and improper mounting and installation techniques, can also lessen the life of a ball screw. For manufacturers hoping to extend the life of their screws, it can be beneficial to order a larger size screw to handle a larger load, prolonging the life of the screw.

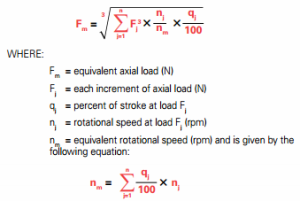

For applications where the loads and/or rotational speed vary significantly, an equivalent load can be calculated using the following formula:

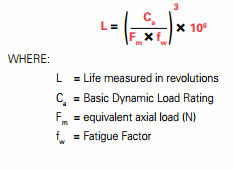

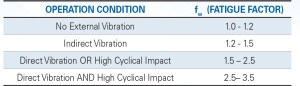

The life required in revolutions is determined by multiplying the total stroke in millimeters by the total number of strokes required for the designed life of the equipment and then dividing by the lead of the ball nut. Ball nut life is greatly influenced by the operating condition, including speed and vibration the assembly may see. A fatigue factor must be considered when calculating life. To calculate the life for a ball nut use the following formula:

Indirect vibration is any vibration associated near the screw mounting which influences the stability of the assembly. Direct vibration pertains to any vibration directly linked to the screw assembly which influences the stability of the assembly. High cyclical impact is any repetitive impact or high deceleration of the ball screw assembly.

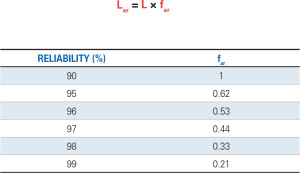

If operation reliability higher than 90 percent is required, then the theoretical life must be corrected by using a reliability factor according to the table.

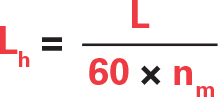

If total time is needed, the following equation can be used to find the life measured in hours:

Instead of hand calculations, here are some charts to help calculate life expectancy:

Metric:

Inch:

![PrecisionBallScrewAssembly[1]](http://www.makingmotionwork.com/wp-content/uploads/2015/07/PrecisionBallScrewAssembly1.png)